pba is the premier brand of AISI 316L stainless steel, the hardest, most resistant and elastic steel. Stainless steel AISI 316L is an austenitic alloy. It is distinguished from others inoxidizable steels by the high percentage of molybdenum which gives it a special resistance to pitting corrosion and stress corrosion. In this kind of stainless steel the nickel’s presence is increased in order to guarantee stability. Furthermore, the “L” stands for low carbon, in fact its quantity is less or equal to 0,03%.

ECONYL® is a 100% regenerated nylon from waste such as fishing nets, old carpets destined for landfills, plastic components and fabric scraps from mills. As well as being a solution on waste, ECONYL® regenerated nylon is also better when it comes to climate change. It reduces the global warming impact of nylon by up to 90% compared with the material from oil.

pba uses Aluminum Alloy 6060, a medium strength heat treatable alloy. It has very good corrosion resistance, very good weldability and good cold formability. It is commonly used for complex cross sections and has a very good anodizing response.

Polyamide 6 is a thermoplastic resin with high mechanical resistance, excellent toughness to impacts and high resistance to wear and abrasion. Classified as a self-extinguishing UL 94V-2 category, polyamide 6 does not generate toxic gases, it is a safe material, hardly deformable and very durable.

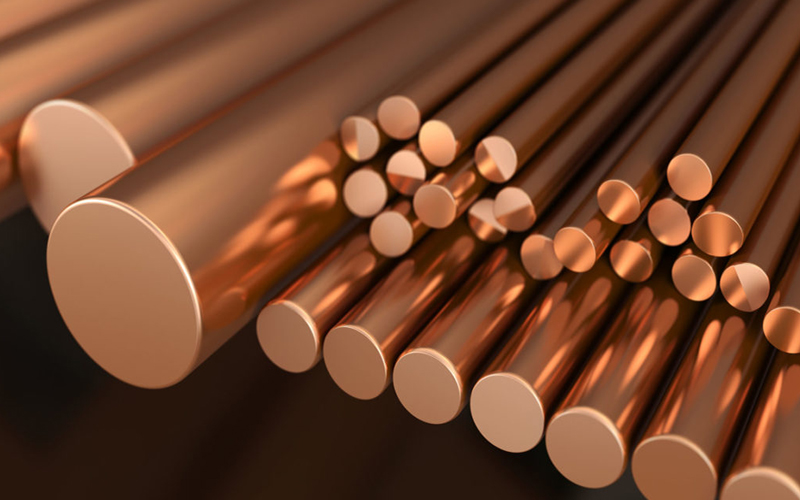

Copper is a ductile, malleable metal, appreciated for its strength and resistance to corrosion. When exposed to air, it oxidizes and develops a protective layer - patina - whose composition and color vary as the weather conditions and elements change. This oxide is proven to give copper antimicrobial properties, killing more than 99.9% of bacteria on its surface within 2 hours from exposure.

Genuine leather is an extremely durable material offering high elasticity, softness and lightness. This fine, natural material may display marks and variations such as lines and wrinkles, and color differences, all signatures that enhance its beauty and excellence.

Wood is a natural lightweight and durable fiber; it is a good insulating material that retains moisture. The main physical properties of wood are durability, hardness, stiffness and density. Pure wood is a refined and natural product totally regenerable and recyclable. Marks, grains and color variations are distinctive features that guarantee its authenticity.

HPL is a high-pressure decorative laminate, in other words a panel consisting of layers of cellulose fibres that are impregnated with thermosetting resins and subjected to a high pressure process consisting in the simultaneous application of heat and pressure. This causes at the same time the fluidization and polycondensation of the resins, resulting in a homogeneous, non-porous material with the required surface finish. HPL is supplied as panels, available in different sizes, thicknesses and surface finishes.

Copper plating is the process of depositing a copper layer onto various metals for functional and decorative purposes. Copper is a chemical element with a high thermal and electrical conductivity, and is antibacterial, tough, ductile and non-magnetic.

The finish is uncover copper plated, thereof, over time copper naturally changes color – transforming from a shiny brown color to darker browns, then blues and finally greens after a number of years. This change in color, due to the natural oxidation called “patina” doesn’t affect the antimicrobial activity that remains constant.

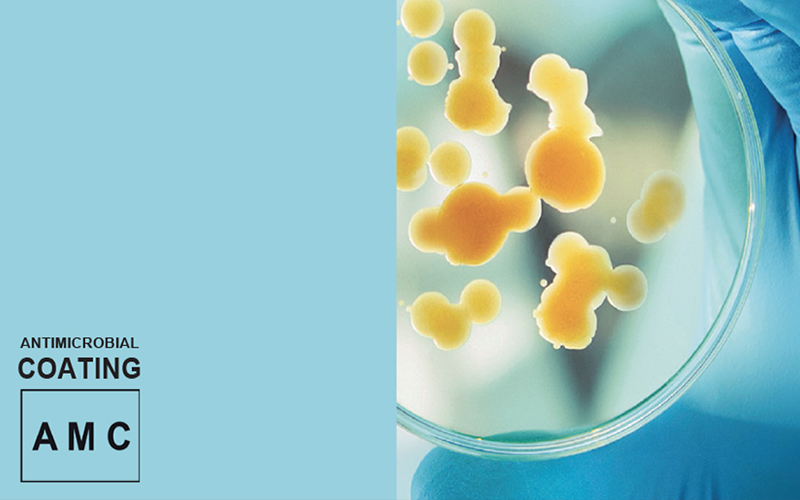

pba ANTI-MICROBIAL COATING (AMC) is a powder-coated containing special silver ions additives that make the surface protected from bacteria and microorganisms. The tests show that on untreated surfaces the microbes and bacteria can easily proliferate, while on AMC surfaces the bacterial proliferation is practically zeroed.

Download Anti-Microbial Coating (AMC) Brochure

The PVD finish (acronym for Physical Vapor Deposition) is a process of the highest technological level which, by means of physical vapor deposition of a thin film of extraordinary hardness, allows to obtain a surface coating with exceptional aesthetic and technical characteristics.